Gothenburg-based Wellspect wanted to make a real difference by developing a new hydrophilic intermittent catheter for women who need help emptying their bladders.

Contact us

Sending Email...

CLIENT CASE - MEDICAL SOLUTIONS - WELLSPECT

Creating an innovative catheter

Uncompromising approach produces innovative catheter

Not everyone is able to empty their bladder when they need to. There can be a number of factors that prevent normal bladder-emptying, meaning that assistance is required. Intermittent self-catheterization (ISC) is a method that can provide a solution for people who have problems emptying their bladders. It involves the use of a hydrophilic catheter; a disposable product that is inserted into the urethra and empties the bladder.

It can be difficult talking about not having normal bladder function and many people put off seeking help. So when Wellspect started developing a new catheter for women, their aim was to make a real difference by offering a hygienic, easy-to-use and convenient hydrophilic intermittent catheter in a discreet container.

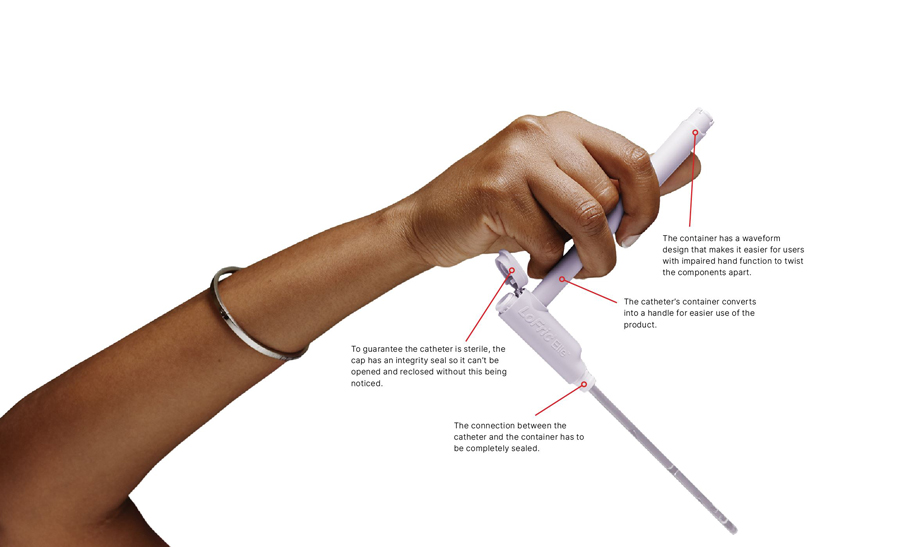

Container doubles as a handle

The result was a catheter with a container that has a number of functions. Not only does it store the lubricant that keeps the catheter moist, but it also connects to the catheter to form an L-shaped handle, making it easier to insert the catheter into the urethra.

The ergonomic L-shaped handle allows women to sit in a more upright position, provides better reach and greater control during catheterization and bladder-emptying. The handle also provides a non-touch technique, preventing the user from getting urine on their hands and making catheterization more hygienic.

The catheter can be put back in the resealable container after use and then placed in a purse and disposed of later on. The outer packaging is made from recyclable material for maximum sustainability.

Interesting challenge

“We’ve been making catheters for Wellspect for some time,” explains Jens Ingemansson, Sales and Project Engineer at Nolato MediTor in Torekov, Sweden. “When Wellspect got in touch and told us about their ideas for this new product, it presented an interesting challenge.

“Our own extensive experience and in-depth knowledge of soft materials were a good match with this project for the catheter components, but we soon realized that the packaging, the container, needed completely different expertise. We knew Nolato Cerbo had these capabilities, as they’re experts in manufacturing pharmaceutical packaging to stringent requirements on sealing and function.”

A key challenge of this project was for the different parts of the container to be completely sealed, retaining the catheter’s lubricant and ensuring the product is ready to use, and that there is no risk of urine leaking out after use. To minimize the risk of complications for the user, the outer packaging also has to be completely sealed to guarantee the product is sterile. So the cap is designed to indicate to the user that it has not been opened previously.

Close collaboration

“Wellspect and Nolato have worked very closely on this,” says Anci Petersson, Sales and Marketing Director at Nolato Cerbo. “The customer provided a design and the functional requirements, which we then helped refine and adapt so that the product meets all the requirements, while also enabling efficient high-volume production.”

Much of the work therefore focused on getting the correct seal between the catheter and the container, and between the different parts of the container. The product also had to be easy to use, including for someone with impaired hand function. So the packaging was devised with a waveform design, allowing the user to twist the components apart instead of having to pull them apart. This was an aspect that required a lot of work to ensure it was sealed yet easy to open.

Exacting functionality requirements

“Our task has been to ensure all the closures are completely sealed during assembly, sterilization, shipping, all the way to the customer,” explains Jens Ingemansson. “But those surfaces that need to be completely sealed when it’s closed also need to have relatively low sliding resistance so that it isn’t too difficult for the user to access the catheter. This work required precision to a couple of hundredths of a millimeter in some cases.”

“The product’s functionality placed stringent requirements on barriers, hinges and closures,” explains Dennis Broberg, Head of Product Development at Nolato Cerbo. “We’re very familiar with these areas because of our work on pharmaceutical packaging.”

For instance, the container has a snap-in lid with an integrity seal, making it easy to open and indicating that the catheter inside the container is unused. The cap can’t be too difficult to break off, but it also has to guarantee that the product is unused.

Cooperation and flexibility

A third Nolato unit was also involved in the product. Wellspect had planned to assemble the parts in-house. But while Wellspect’s assembly line was being completed, Poland-based Nolato Stargard helped out with manual assembly.

“The significant possibilities for cooperation and flexibility offered by Nolato throughout the project, combined with us constantly trying to respond to customer needs, are key aspects of providing clients with great service and support,” adds Anci Petersson.

The catheter’s innovative function and design have garnered both an iF Design Award and a Red Dot Award for outstanding design. In 2021, the product also received the UK’s Look Good Feel Good Award from a judging panel of healthcare personnel and catheter users.

- Nolato MediTor

- Nolato Cerbo

- Nolato Stargard

- Medical Devices

- Pharma

- Medical Excellence

- Medical Solutions

- Injection molding of plastics

- Nolato Magasin

You might also be Interested in

MEDICAL EXCELLENCE

Creating world-class operations

COMPANIES

Local yet global presence

OUR OFFERING