A virtual prototype is a digital version of a new component. Instead of creating it in the real world, it is created on a computer, ready for testing in the virtual world.

Contact us

Sending Email...

SERVICES

Virtual prototyping

Digitalization has introduced many buzzwords. One of these is 'virtual prototyping', which is creating new opportunities for medtech companies to save time and money.

Computer-based testing

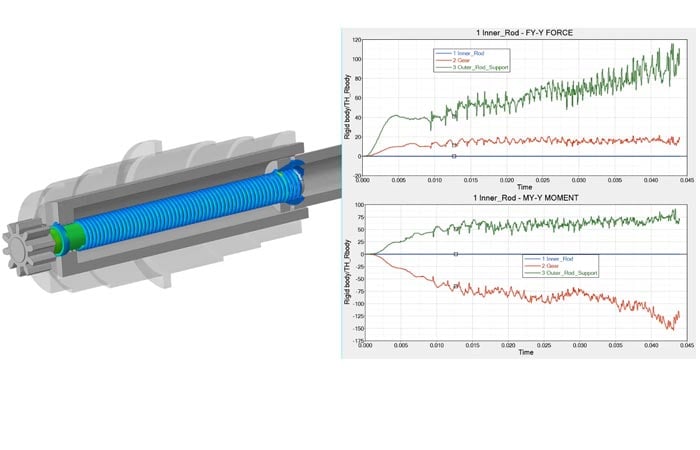

The real benefits of virtual prototyping can be seen when a virtual component is incorporated into a complete virtual product, as this allows testing to start immediately.

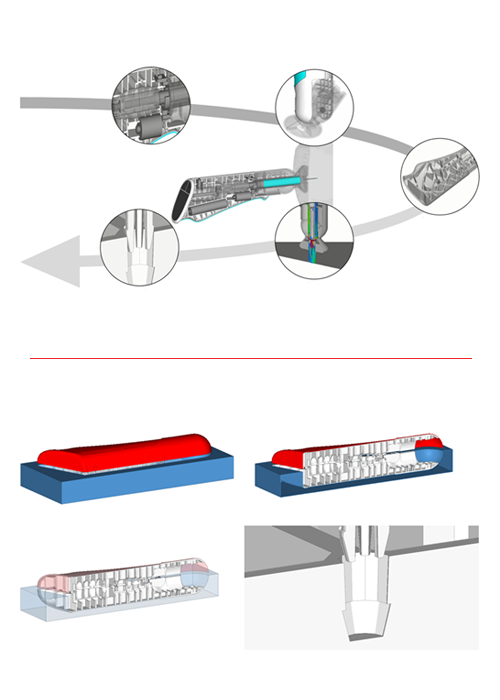

Medical autoinjector

Applying integrated, simulated design solutions early on at the design stage of development reveals any problems before producing a physical prototype or the associated manufacturing tooling.

Virtual products, real people

Building experience into virtualization combines an understanding of real prototypes and manufacturing with insights from the digital world.

A powerful tool

Virtual prototyping is an amazingly powerful tool for avoiding delays and costs. Identifying an issue early on in the process saves both time and money.

Getting it right from the start

Virtual prototyping helps get things right from the start.

VIRTUAL PROTOTYPING

Our knowledge, your opportunities

Our know-how brings better products to market quickly and can help people with medical conditions; real people and real lives enhanced and extended by virtual prototyping.

VIRTUAL PROTOTYPING

The Nolava project

Creating a virtual prototype takes into account everything that happens to the materials when they are processed during manufacturing.

The Nolava project was a joint venture between Nolato, Avalon, Altair and Ariadne. Its purpose was to create a fictitious but realistic medical device to showcase the different techniques used during product development. Nolato focused on using virtual prototyping, which uses manufacturing simulation results to improve the function of the final product. Manufacturing methods such as injection molding and assembly can also be simulated.

Contacts

If you would like more information about Nolato's services and solutions please contact our team member(s) below.

Bill Torris

Technical Design Center - The Americas

Patrik Ingvarsson

Technical Design Center - Europe

Mattias Bengtsson

Technical Design Center - Asia

You might also be interested in

MEDICAL EXCELLENCE

Creating world-class operations

Medical Excellence is our way of creating world class operations inspired by the Nolato spirit, our strategies, quality standards and our lean processes and tools. Together, these elements create a framework for managing resources efficiently and increasing value for our customers.

SERVICE

Tool manufacturing

Nolato is a leader in the design and manufacture of precision injection molds, from single- to ultra-high-cavitation molds across many industries.

SERVICE

Injection molding of silicone

Nolato has over 40 years' experience in delivering cost-effective solutions for precision liquid silicone rubber (LSR) components and assemblies.