Dip molding

Dip molding technology offers unique product design possibilities. Based on our extensive experience, we can support you from short-time prototyping to robust and validated production. Our consistent output of high-quality products ensures your requirements and expectations are met.

Your dip molding partner

Nolato is one of the largest producers in the world for dip-molded anesthesia breathing bags. We have been chosen as a partner by the market leaders in the anesthesia machines and breathing circuit markets and our catheter balloons are used worldwide.

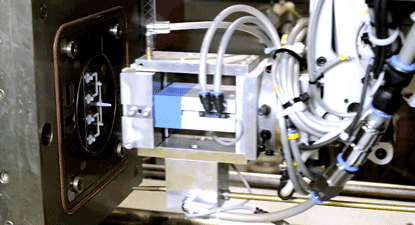

Automated production line

Nolato has a modern and highly automated production line, which ensures consistent high quality as well as significant capacity.

In-house expertise

Nolato has the know-how and technology to produce high-quality flexible, airtight liquid latex products. Complex components can be dipped easily due to the materials' high elasticity. In-house prototype tools mean low tool investment costs and short lead times.

Materials

We process both synthetic and natural latex rubber. Both Nolato materials and customer-specific formulations are available.

Dipping environments

Nolato provides manufacturing in hygiene rooms and Class 8 cleanrooms with robust and validated processes.

Extensive offering

We offer both dipped standard products, such as breathing bags and premium catheter balloons, and a wide range of dipped customized components for medical customers with stringent demands.