In the world of electronics and mechanical engineering, managing heat effectively is crucial for reliability and performance.

Contact us

Sending Email...

Contact person/s

Jonas Carlsson

Director Global Sales

+46 708 12 99 95

STANDARD PRODUCT

Compatherm® Thermal Paste

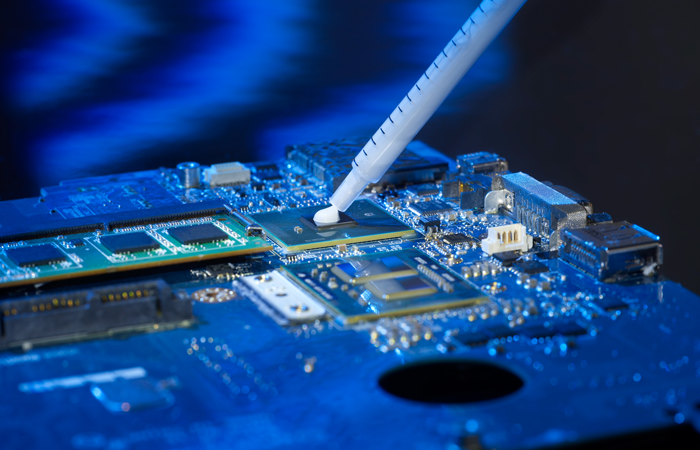

Compatherm Paste, a thermally conductive paste, provides thermal conductivity, bridging the gap between components and cooling solutions to ensure devices operate within safe temperature limits.

COMPATHERM® PASTE

The Significance of Thermal Paste Conductivity

Falling into the thin-bond-line category of Thermal Interface Materials (TIMs), it is engineered to form the thinnest possible film between the heat source and the heat sink. This minimal thermal resistance is key to its effectiveness. The high thermal conductivity of the paste ensures efficient heat dissipation, crucial for maintaining the integrity and longevity of electronic components.

Compatherm® Thermal Paste Benefits

Thermal paste with high performance and ultra-thin bond line

Maximizes heat dissipation with minimal thermal resistance, leveraging an ultra-thin bond line for superior thermal management in high-power devices.

Precision bond lines down to tenths of microns

Enables exceptionally thin bond lines, down to tenths of microns, for precise thermal control in densely packed electronic configurations.

Versatile dispensability and printability

Facilitates easy application via dispensing or silk/stencil screen printing, ensuring consistent, high-quality thermal interface across various manufacturing processes.

Stable composition without dry-out

Maintains consistent thermal conductivity and performance over time, with a stable composition that resists drying out, ensuring long-term reliability.

compatherm® paste material matrix & datasheets

| Test standard | Unit | 9532 | 9543 | 9550 | ||||

| Base matrix | Silicone |

Silicone | Silicone | |||||

| Thermally conductive filler | Ceramic | Ceramic, Al | Ceramic, AI | |||||

| Color | Visual | White | Gray | Gray | ||||

| Thermal Conductivity | ISO 22007-2 mod | W/(m-K) | 2.5 | 4.3 | 5.0 | |||

| Viscosity | Brookfield 10rpm | cP |

110,000 | 250,000 | 200,000 | |||

| Density | ASTM D792 | g/cm^3 |

2.68 | 2.3 | 2.20 | |||

| Dielectric Breakdown Voltage | ASTM D149 | VAC/mm |

4 000 | 400 | 1 000 | |||

| Volatile Content | ASTM E595 (mod.) | % |

0.3 | 0.3 | 0.15 | |||

| BLT (Bond Line Thickness) | um | 50 | 20 | 20 | ||||

| Shelf life | month | 12 | 12 | 12 | ||||

You might also be interested in

CAREERS

Careers in Sweden

We are a responsible employer that supports its employees and provides expert services for our customers. Nolato has strong core values, in which both professional development and personal wellbeing are key drivers for a successful company.

STORIES

Enhancing optical module performance

Nolato Materials, specialize in delivering cutting-edge EMC and thermal solutions for optical module manufacturers, helping them meet the growing demands for data, cloud, and 5G services.

STORIES

Cool running with silicone-based thermal interface material

Some issues have been raised regarding silicone in electronics. Consequently, in spite of their often-disadvantageous aging, thermal stability, and stiffness properties, PLP TIM products with non-silicone-based matrices have been gaining in popularity. This article by the R&D department of Nolato Silikonteknik addresses these concerns and underlines the benefits offered by silicone: