By adopting R-strategies—such as reuse, repair, and recycling—we aim to minimize resource use and reduce waste.

Contact us

Sending Email...

STORY

R-thinking key to developing new products

R-Thinking: Innovating for a Circular Economy

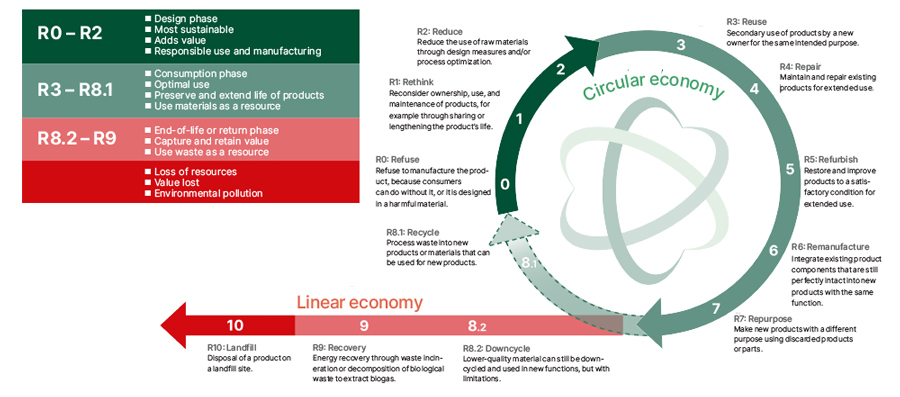

Achieving a circular economy, in which we use resources more economically and reuse them instead of basing value on constantly adding new resources, is a change that more and more people consider necessary to bring about a sustainable society for the future. In this regard, R-strategies are an important part of rethinking and innovating around resource use when developing new products.

Adopting a circular mindset

Human consumption has long been based on a linear approach. We create a product, use it and then throw it away. This mindset has kept things going at a rapid pace. But resources such as raw materials and energy have been used at a high rate, which doesn’t fit with today’s holistic approach to sustainability.

To change this, we need to adopt a circular, rather than a linear, mindset. Systematically reducing resource losses through smarter use and manufacturing that enable the product, or at least its components and materials, to be used for longer or in other forms.

Less is more

The less resources and virgin raw materials that are needed for manufacturing, the more circular it will become. But a completely circular approach is neither possible nor desirable, as this would require huge resources to utilize all the constituent parts of the expended products.Nolato Magasin has previously written about the importance of taking a circular approach to designing products. It’s at the drawing board that a product’s sustainability performance is determined.

Holistic approach essential

A holistic approach that takes account of a product’s purpose is what’s needed to ensure the product is sustainable. Is it really needed? By far the most sustainable option is to not manufacture a product. Or should it have a different design? Can it be made so it’s easy to repair when it breaks? Can it be refurbished? Can it be used as something else when it has reached the end of its useful life? Or ground down and its material recycled?

There are lots of options, but it’s also important to get the level right so it doesn’t end up being counterproductive.

Find the appropriate degree

R-strategies, which have existed for some years, help determine the level of circularity that might be appropriate when manufacturing a new product. The ‘R’ comes from ‘reuse’, ‘recycle’, etc. The strategies includes 11 different actions ranked according to the level of circular economy that they contribute to. The lower the number, the higher the level of circularity.

R0 to R2 are aimed at avoiding or reducing new raw materials in manufacturing, while R3 to ¤R7 are based on retaining resources within the system, thereby reducing the need for new raw materials.

If it’s not possible to apply any of the methods in R0 to R7, the methods in R8 to R9 may at least generate a satisfactory positive environmental impact.

Combining multiple R-strategies

Despite the R-strategies’ hierarchical structure, the optimal sustainable strategy is always case-specific and should be based on a holistic, system-wide approach that often draws on a number of R-strategies. The order in which they are ranked provides an indication of what actions will have the greatest impact and the order in which they should be selected.

The purpose of the R-strategies is to encourage everyone involved to start thinking innovatively (they should perhaps be called ‘R-thinking’) to more easily identify the basis for adapting a new product to a more circular economy.

- Nolato

- Sustainability

- Nolato Magasin

You might also be interested in

STORIES

Moving to a brand-new plant

STORIES

EMC gaskets – development trends

STORIES