Nolato has extensive experience in a wide range of cutting techniques. These are often combined to offer an optimal solution.

Contact us

Sending Email...

Contact person/s

Jesper Johansson

Sales

+46 732 32 67 13

SERVICE

Flatbed punching

We offer world-leading manufacturing quality and capacity of traditional and advanced die-cut parts in both standard and cleanroom environments.

Wide range of projects

We offer experience in a broad spectrum of projects across most industrial sectors and expertise in the properties and best uses of various materials, on their own or in combination.

Materials

We use the very best of a variety of materials, on their own or in combination with each other.

High quality

We offer both the highest quality and competitive prices in our supply of materials to meet specific customer needs.

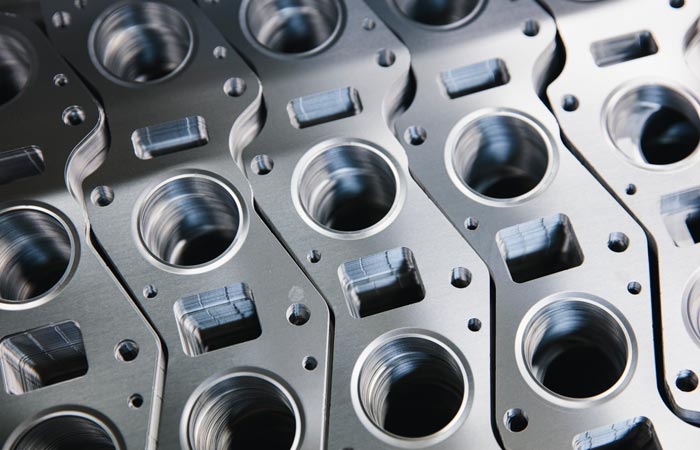

Die-cutting

Nolato uses flatbed die-cutting to manufacture gaskets for the automotive sector and general industry.

Cooperation

We work with the world's leading materials manufacturers.

TECHNOLOGY

Close cooperation with our suppliers means that we can influence the development of materials, which ultimately benefits our customers.

PRODUCTION

Nolato also uses flexible and efficient production equipment that can handle most jobs, from short series to long production runs.

You might also be interested in

SERVICE

Assembly solutions

Our expertise and experience in assembly solutions allow us to always offer the right degree of automation.

SERVICE

Die-cutting technologies

We offer world leading quality and capacity of traditional and advanced die cut manufacturing in both standard and cleanroom environment.

SERVICE

Tool manufacturing

Nolato is a leader in the design and manufacture of precision injection molds, from single- to ultra-high-cavitation molds across many industries.