Nolato offers a wide range of technologies to achieve the look you want for your product.

Contact us

Sending Email...

Contact person/s

Mattias Bengtsson

Technical Design Center - Asia

SERVICE

Decoration technologies

By combining different technologies, you can create almost endless decoration possibilities.

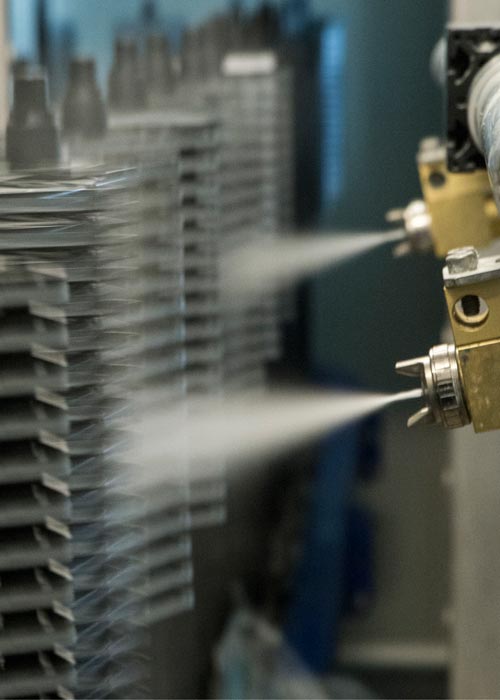

Painting

Nolato offers many types of painting finishes, including high gloss, soft touch, gradient, tactile and antibacterial. We have fully automated paint lines with up to four separate paint layers, each applied in ISO 14644-1 Class 7 cleanroom environments. We use waterborne paint systems, as well as UV and PU-based systems.

Nolato ImageTech™

By using a combination of printing methods, you can create patterns, visual effects and even photos and images to enhance the uniqueness and usability of your products. This includes 360° decoration technology that wraps around the product.

Metallization (NCVM)

We create a one-atom-thick metal surface so thin that the layer isn't conductive. This offers new cosmetic and functional opportunities.

Nolato ClearTech™

Nolato's proprietary coating technology offers a superior wear-resistant hard coat with excellent optical performance and an absolute minimum of paint build-up.

In-mold decoration (IMD) & In-mold label (IML)

Cosmetic decoration and increased scratch resistance of plastic part surfaces using pre-printed foils loaded into the injection molding process.

Nolato LogoTech™

We offer a variety of new and eye-catching logo solutions, creating highly decorative, eco-friendly and cost-effective logo solutions.

Laser marking

We can provide an indelible, high-contrast mark below the top coat that guarantees it will never wear off.

Nolato SurfaceTech™

We create very high-resolution surface 3D textures and patterns for an enhanced look and feel for plastic parts.

Printing

We offer tampo printing, screen printing, heat transfer and dye sublimation.

TECHNOLOGY

Experience of advanced technologies

Nolato has 20 years' experience of developing, refining and using advanced decoration technologies for manufacturing products with substantial cosmetic content, such as mobile phones and other consumer electronics.

PRODUCTION

In-house production

All processes are carried out in-house, providing our customers with good project control, optimal quality and short lead times.

You might also be interested in

SERVICE

Injection blow molding

Nolato's extensive experience in injection blow molding (IBM) provides a range of design opportunities for your containers.

SERVICES

Scientific injection molding

Nolato has taken injection molding to the next level by using scientific injection molding (SIM), which ensures the highest-quality product over a program's life cycle, regardless of molding machine, material or manufacturing location.

SERVICE

Ceramic injection molding

Nolato is one of few global players who specializes in fine ceramic molding of small functional/mechanical/cosmetic products.