Contact us

Sending Email...

Contact person/s

Glenn Svedberg

Group Sustainability & Technology Director

OUR APPROACH TO DESIGN

We push for sustainability already at the drawing board

Our approach to design is that we push for sustainability already at the drawing board, where we contribute with our extensive knowledge and expertise. Thereby, we strive to ensure that various environmental and ethical aspects are considered at the beginning of a product’s life cycle.

We present this with following focus areas & claims

- Our Eco-Design Model

- Improving circular flows

- Ensuring ethical use

OUR ECO-DESIGN MODEL

We optimize the overall environmental impact of our customers’ products early in the design phase

We optimize the overall environmental impact of our customers’ products already at the design phase by evaluating the selection and production of materials, the design of product components, how products are assembled and used, and how the recyclability of the end-product may be optimized.

Our ECO-Design - Virtual factory

By combining virtual tools such as mold flow simulation, mechanical simulation software, and virtual measuring software, we may predict the final result, help customers to understand the core function of the parts and evaluate how the end-product will function in real life. This may have considerable effects on the choice of materials and product design, which ultimately improves environmental optimization in a highly cost-efficient way.Material selection - Choice of material

The choice of material has a significant effect on the sustainability of an end-product. Plastic often has a lower carbon footprint than both glass and metal and through careful evaluation Nolato finds the solution best suited to the customer’s needs, both from a cost and environmental perspective.Resin manufacturing - Production of material

We evaluate the chosen plastic raw material to find renewable alternatives, such as through bio-based, recycled or mass balanced options. We also consider where the product is to be made and whether renewable energy is used during the raw material manufacturing process.Component design & manufacturing - Component product and design

By carefully considering the product’s design and components, we may improve its environmental optimization in terms of resource usage, weight, manufacturing method, transportation, energy consumption and material scrap.Assembly method

By evaluating the choice of assembly method, we may affect several circularity aspects such as opportunities to repair, refurbish, upgrade and separate the product prior to final recycling.Product use

We assess the product’s passive or active properties, which means whether the end-product will continue to consume resources when used. By understanding the application and life-cycle of the product, we can advise our customers on the most appropriate solutions.End of life - Recycling

We evaluate the end-product to see if it can be repaired or refurbished to extend its lifespan, and whether a component can be manufactured in a single material (mono-material), which makes it easier to sort for recycling.improving circular flow

We advice our customers on how to improve the circular flows of their products

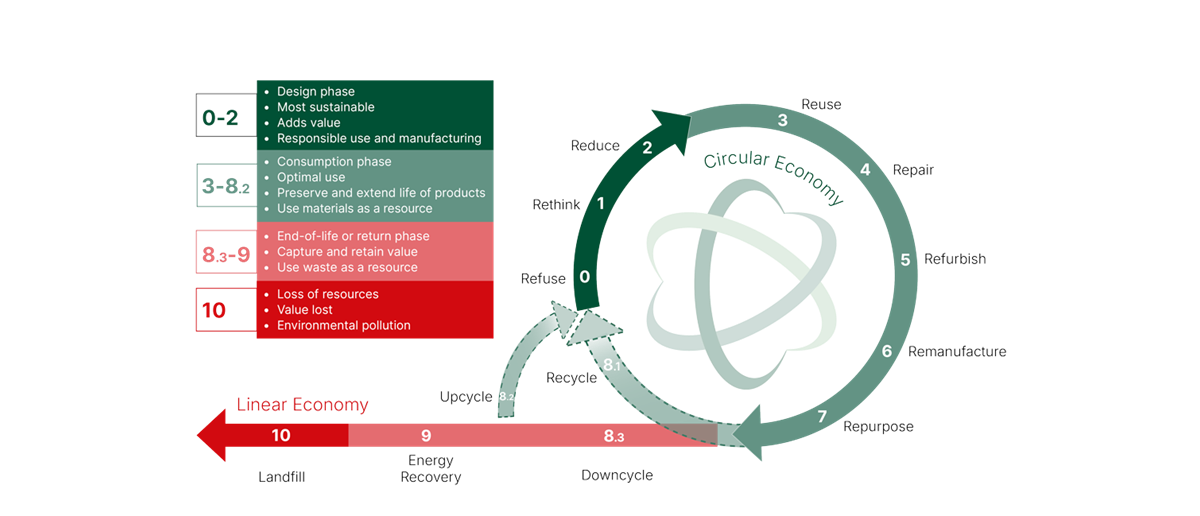

Using the “R-strategy”, we advise our customers on how to improve the circular flows of their products. It revolves around reevaluating the intended end-product by considering how design may affect aspects such as product usage, resource consumption, and recyclability, and other measures that may prolong product life through maintenance, repair, and secondary usage.

Following the “R-strategy”

We council our clients based on the R-strategy, which offers different ways to improve the circularity of a product.Refuse: Focus on creating value

We assess our customer’s intended product based on life span, end-of-life, raw materials consumption, and intended product application. If we consider it to be detrimental based on these aspects, we may advise our customer to abstain from manufacturing it or decline the opportunity.Rethink: Reimagining how products are used

By considering the possibilities of sharing or prolonging the life span of a product, aspects such as ownership, product usage and maintenance could be reevaluated.Reduce: Smart use of resources

By suggesting various design measures or process optimization, we advise our customer on how to reduce the use of various resources, such as raw materials and energy.Reuse: Prolonging the life of products

By considering the possibilities of secondary use, a product’s life span may be extended.Repair: Taking care of products

By considering the ability to maintain and making it possible to repair an existing product, the customer may extend the life span of the product.Refurbish: Restoring functions

By considering the ability to restore and improve the functions of an existing product, the customer may extend the life span of the product.Remanufacture: Continuing the life of components

We advise our customer on the possibility of integrating selected intact product components from discarded products into new products with the same function.Repurpose: Giving products a new life

We advise our customer on how to repurpose discarded products or components in the production of new products.

Recycle: Designing for recyclability

By considering recyclability of the end-product already in the design phase, such as using mono-materials and assembly methods that enable disassembly, materials may be used in the production of new products.

Upcycle

Lower quality raw materials from other products can be upcycled and used, e.g by chemical recycling.

ENSURING ETHICAL USE

We ensure the ethical use of our products by being prepared to decline business that conflicts with our standards

We actively review and evaluate potential business opportunities and we are prepared to decline those that we consider would be in conflict with our ethical standards regarding human rights, environmental impact and responsible business conduct including the product application.

Preventing non-ethical application

We are firmly against our products being associated with illegal activities, human rights abuses, environmental harm, and corruption and have therefore implemented a non-ethical business exclusion policy.Review and evaluation

Before entering new or expanded business, we conduct a review of the intended products to assess their ethical implications. The review considers factors such as environmental impact, human rights, labor practices and potential harm to society. If the products are deemed unethical, we reserve the right to exclude them or decline the business.Training and awareness

Nolato’s employees receive training on our non-ethical business exclusion policy, particularly those involved in client relationships and new business, to ensure that they are aware and able to uphold our principles.You might also be interested in

STORIES

R-thinking key to developing new products

At Nolato, we believe in rethinking how products are designed to support a sustainable future. By adopting R-strategies—such as reuse, repair, and recycling—we aim to minimize resource use and reduce waste.

STORIES

Eco-design: The drawing board is the best stage to environmentally optimize a new product

Nolato has established an eco-design model to support its customers. The model aims to make it easier to minimize the overall environmental impact of new products. Read more here.

RESPONSIBLE BUSINESS CONDUCT

Nolato establishes a non-ethical business exclusion policy

To conduct our business operations in a socially responsible and ethical way is fundamental for us. As part of this, we recognize the importance of ensuring that the products we manufacture are not used in non-ethical applications.